|

CMCC Industries company limited

|

LSZH fire resistant cables

| Place of Origin: | Sichuan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

After LSZH fire resistant cable is completed with aluminum interlocking armor process, mastering the basis of performance and complete production proc

Description: After LSZH fire resistant cable is completed with aluminum interlocking armor process, mastering the basis of performance and complete production process LSZH insulation materials on the sheath material. UL laboratory products to the United States, the Wuhan High Voltage Research Institute network, national wire and cable Quality Supervision and Inspection Center (Shanghai Electric Cable Research Institute), the National Fire Protection Building Materials Quality Supervision and Inspection Center, Guangzhou electrical safety testing and other testing authority, the performance are in line with the standard requirements.

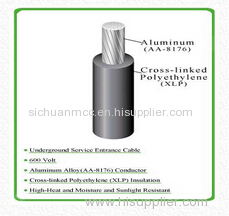

Main features: organic flame retardant LSZH independent research and development, added to the silane XLPE compound, much better than the traditional inorganic flame retardants, have excellent electrical properties and anti-aging properties, long life, excellent flame retardant properties, can reach Diyanwulu level, more safety and environmental protection. ① high rare earth iron aluminum alloy conductor material, ② fire-resistant mica, ③ halogen flame retardant silane XLPE insulation, ④ retardant fiberglass wrapping tape, ⑤ aluminum with interlocking armor, ⑥ polyolefin jacket.

Fire retardant characteristics: pure aluminum cable is flame resistant level is very low, not to involve a higher level of fire safety in place, and we have designed a high rare earth iron alloy conductors, fire-resistant mica tape, fire retardant silane crosslinked polyethylene insulation, fire retardant fiberglass tape around the package, the halogen flame retardant polyolefin jacket, aluminum with interlocking armor, aluminum cable LSZH polyolefin outer sheath of this structure can withstand 750 ~ 800 ℃ under fire retardant test 40min, reaching retardant IA level, refractory grade I, applicable to the higher level of fire safety in place.