|

CMCC Industries company limited

|

flame retardant cable flame retardant cable

| Place of Origin: | Sichuan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Excellent performance when only one of the conductors

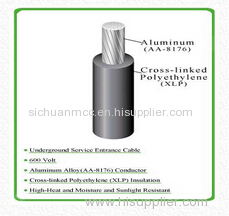

Flame retardant properties: Excellent performance when only one of the conductors, the cable insulation with flame-retardant silane crosslinked polyethylene, according to different requirements to achieve different levels of flame-retardant, flame retardant for a higher level of FT4 level, its combustion: flame retardant properties along the combustion is not, does not drip, and the combustion halogen, greatly improve the security level used. Plus aluminum structure with interlocking armor and halogen polyolefin sheath can withstand 750 ~ 800 ℃, 40min flame burning, no burning and dripping appear along, and can continue to supply, to flame IA class standards.

Conductivity: conductivity of aluminum is 61.5% IACS copper material most commonly used benchmark, the carrying capacity is 79% copper, aluminum superior standard. However, in the same volume, the actual weight of the aluminum is about one third of the copper. According to this calculation, to meet the performance of the premise of the same conductivity, the same length is twice the weight of aluminum cable copper cable. Therefore, the weight of the same current carrying capacity of the cable is approximately half the aluminum copper. Using aluminum to replace copper cables, the cable can reduce weight, reduce installation costs, reduce wear and tear of equipment and cables to make installation easier.